Products

Contact Us

Shandong IRO Polymer Chemicals Co., Ltd.

Shandong IRO Polymer Chemicals Co., Ltd.

Tel : +86-532-66888207

Fax: +86-532-85028486

Web: www.iropolymer.com

Email: inquiry@iropolymer.com

contact@iropolymer.com

|

Your current position: Home > Products >> Textile Auxiliaries |

Diallyldimethylammonium Chloride (DADMAC)

CAS No.: 7398-69-8

EINECS: 230-993-8

Molecular Formula: C8H16

Molecular Weight: 161.5

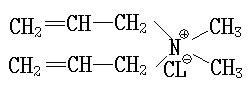

Structural Formula:

Properties:

Diallyldimethylammonium chloride (DADMAC) demonstrates adaptability in the textile printing and dyeing industry. Its structural and performance characteristics support process application requirements.

This substance has the molecular formula C8H16ClN and features a quaternary ammonium cyclic double bond structure. Its charge density reaches +1/161.67 g. At room temperature, it appears as a colorless to slightly yellow transparent liquid. It is highly soluble in water but insoluble in organic solvents such as benzene and chloroform. This property facilitates its formulation and use in water-based dyeing and finishing systems.

Its double bond polymerization rate constant is approximately 3.2*102 L/mol/s in aqueous solutions at 50°C. It copolymerizes with monomers such as acrylamide, acrylic esters, and AMPS. Introducing cationic blocks optimizes the polymer's adsorption and binding capabilities, meeting requirements for fiber modification or dye bath stabilization.

Diallyldimethylammonium chloride exhibits low susceptibility to hydrolysis within a pH range of 3~11 and does not begin weight loss until temperatures exceed 130°C. This performance aligns with conventional textile dyeing and finishing temperature windows. It maintains stable properties under fluctuating pH conditions and heating processes, supporting uniform dye uptake and enhanced color fixation during printing and dyeing operations.

Specification:

| Item | Index | |

| Appearance | Colorless to slight-yellow liquid | |

| Effective content | ≥60% | ≥65% |

| pH | 5.0~7.0 | 5.0~7.0 |

| Chroma | ≤50hazen | ≤50hazen |

| Sodium chloride | ≤1.0% | ≤1.0% |

Applications:

As a cationic monomer with high positive charge density, DADMAC's molecular structure endows its polymerization products (PDADMAC and its copolymers) with dual core applications in the textile printing and dyeing industry. In the front-end dyeing process, PDADMAC serves as a formaldehyde-free fixing agent. In the back-end wastewater treatment stage, PDADMAC-based cationic flocculants leverage their high charge density to rapidly neutralize the negative potential of dye colloids in textile wastewater. This promotes efficient flocculation of colloidal particles, achieving rapid and deep removal of wastewater color.

1. Formaldehyde-Free Fixing Agent

As a formaldehyde-free fixing agent, this represents its most widely used application. The mechanism involves the positive quaternary ammonium group of PDADMAC forming a 1:1 ionic bond (lgK≈6.8) with the sulfonic acid group (-SO₃-) in reactive, acid, and direct dyes. Simultaneously, it forms a film on the fiber surface, preventing dye migration.

The practical effect is remarkable. When treated with a 60 g/L concentration (pH 6, 40°C*20 min), the wash fastness of Reactive Blue GB can be improved from level 3 to levels 4~5. Sweat fastness reaches level 4. Moreover, the color difference ΔE remains below 0.5. This outperforms traditional dicyandiamide-formaldehyde resins (ΔE 1.2), meeting both environmental and color difference control requirements.

2. Flocculant

In dyeing wastewater decolorization, PDADMAC demonstrates outstanding performance as a flocculant. Its high positive charge density neutralizes the zeta potential of dye colloids within one second, shifting the potential from -30 mV to +5 mV.

Typical Treatment Process. First, add 15~30 mg/L of PDADMAC (based on 40% stock solution). Then introduce 0.5 mg/L of APAM for auxiliary bridging. This achieves 90~98% color removal efficiency while additionally reducing CODcr by 20~30%. Sludge volume is reduced by 40% compared to the PAC method, balancing high efficiency with low sludge generation.

Usage:

1. Polymerization Preparation Process

Serving 40% DADMAC aqueous solution as the monomer feedstock. Azobisisobutyronitrile hydrochloride (AIBA) at 0.05% is added as the initiator. The mixture reacts for 4 hours at 70°C under nitrogen atmosphere, yielding a liquid PDADMAC product with a mass fraction of 30%~35%. This product has a weight-average molecular weight (Mw) of 1*105~5*105 and can be supplied directly to dyeing plants without secondary processing.

2. Dye Fixation

Dye fixation processes are categorized into immersion and pad-dry methods, with specific operational procedures and precautions outlined below.

Padding Method. Use 1.5%~3% PDADMAC based on fabric weight (o.w.f.), maintaining a liquor ratio of 1:10. After padding at 40°C for 20 minutes, dewater the fabric and complete fixation by drying at 100°C for 2 minutes.

Padding-Curing Method: Prepare a working solution of PDADMAC at 20~30 g/L, adjusting pH to 6~7. After padding, maintain fabric wetness at 70%. Pre-dry at 100°C for 2 minutes, then cure at 160°C for 45 seconds.

Important Notes: Curing temperature must be strictly controlled. Exceeding 170°C may cause fabric yellowing, resulting in color difference ΔE > 1.0 and compromising dyeing quality.

3. Decolorization of Textile Dyeing Wastewater

Pre-treatment. First adjust the pH of the dyeing wastewater to 7~8 and agitate rapidly at 250/s to prepare for chemical mixing.

Chemical dosing. Initially add 15 mg/L PDADMAC, stir for 30 seconds, then add 0.5 mg/L APAM as a flocculant aid.

Agitation and Sedimentation. Subsequently, slow agitation at 50/s is maintained for 8 minutes to promote floc growth. The treated supernatant exhibits a color intensity < 50 times, with flocs having a median particle diameter (d50) of approximately 2 mm and a sedimentation rate of 2.5 m/h, achieving efficient solid-liquid separation.

Packing and storage:

Packed in a 200kg/plastic drum or 1000kg/IBC drum.

DADMAC can be stored in a cool (4~30℃) to avoid freezing and heat. We certify that DADMAC at correct storage will meet sales specifications for 12 months from the date of manufacture.

Synonyms:

DADMAC polymer; diallyl dimethyl ammonium chloride polymer; China diallyl dimethyl ammonium chloride; Nsc59284; Elionfix G conc; 65% Diallyldimethylammonium Chloride Solution; Diallyldimethylammonium Chloride (60% in Water)